Zart Oz Clay

Air-Dry Clay with the Properties of Natural Clay

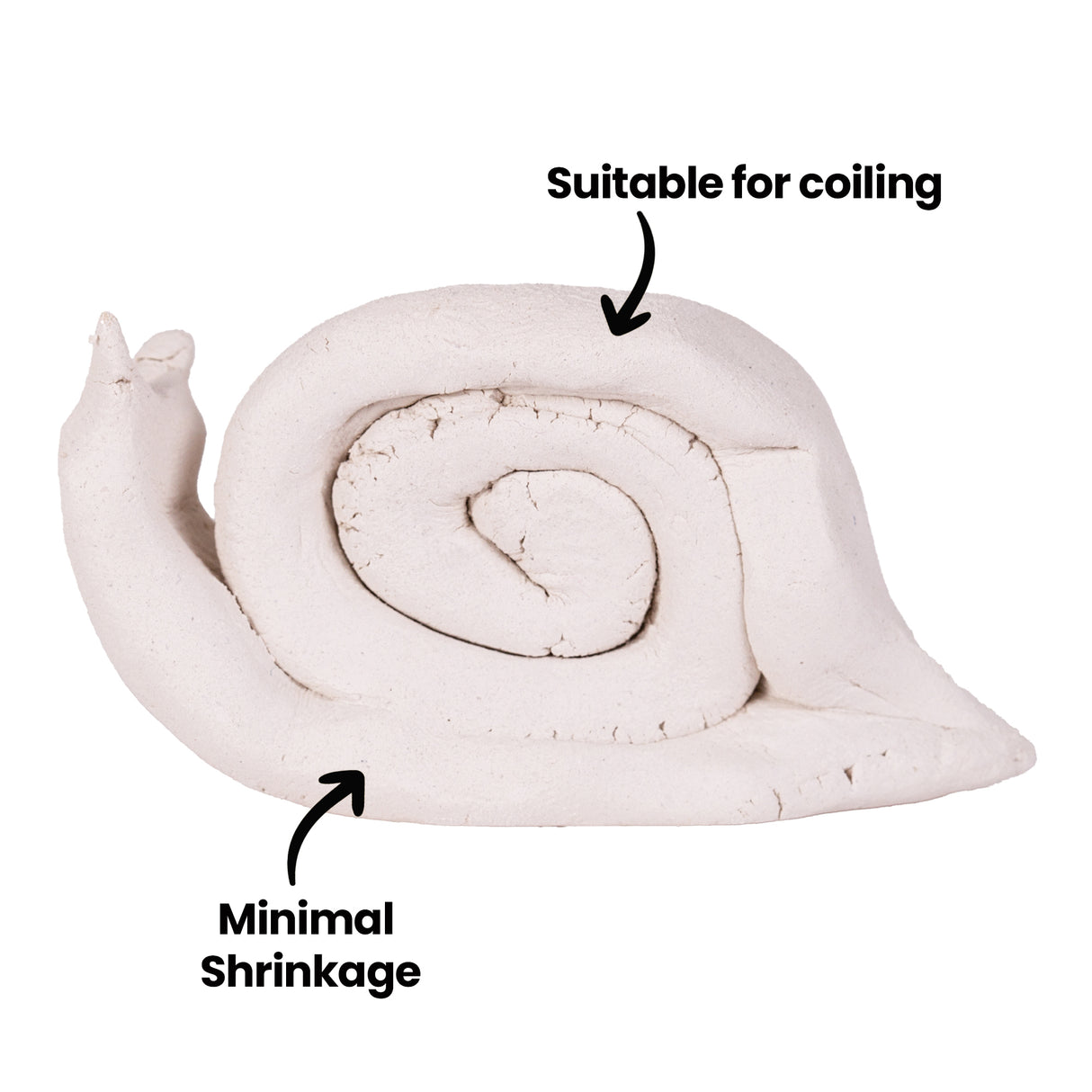

Zart Oz Clay is an Australian-made air-drying clay, offering an affordable and accessible alternative to traditional kiln-fired clay. Designed for classroom use, this versatile, natural-feel clay allows students to develop essential sculpting skills without needing a kiln. Available in 2kg or 5kg, it air dries with minimal shrinkage, making it perfect for constructing larger forms over armatures such as newspaper, wire, or foil, reducing the amount of clay needed. If the clay becomes too firm or starts to crack, simply add a small amount of water to soften it. Once dry, artworks can be painted with acrylics or other water-based paints. For extra durability, coat with a layer of Zart Podge for indoor use, or apply several coats of Zart Outdoor UV Sealer for outdoor use. Store unused clay wrapped in plastic in a cool place to maintain its workability.

Zart Oz Clay - 2kg is out of stock. Estimated arrival October 1, 2025.

Couldn't load pickup availability

Oz Clay: Modelling over an Armature

-

-

Step 2:

-

Step 3:

-

Step 4:

-

Step 5:

-

Catalogue Page Number